Understanding Aeroplane Chords

Definition of aeroplane chords

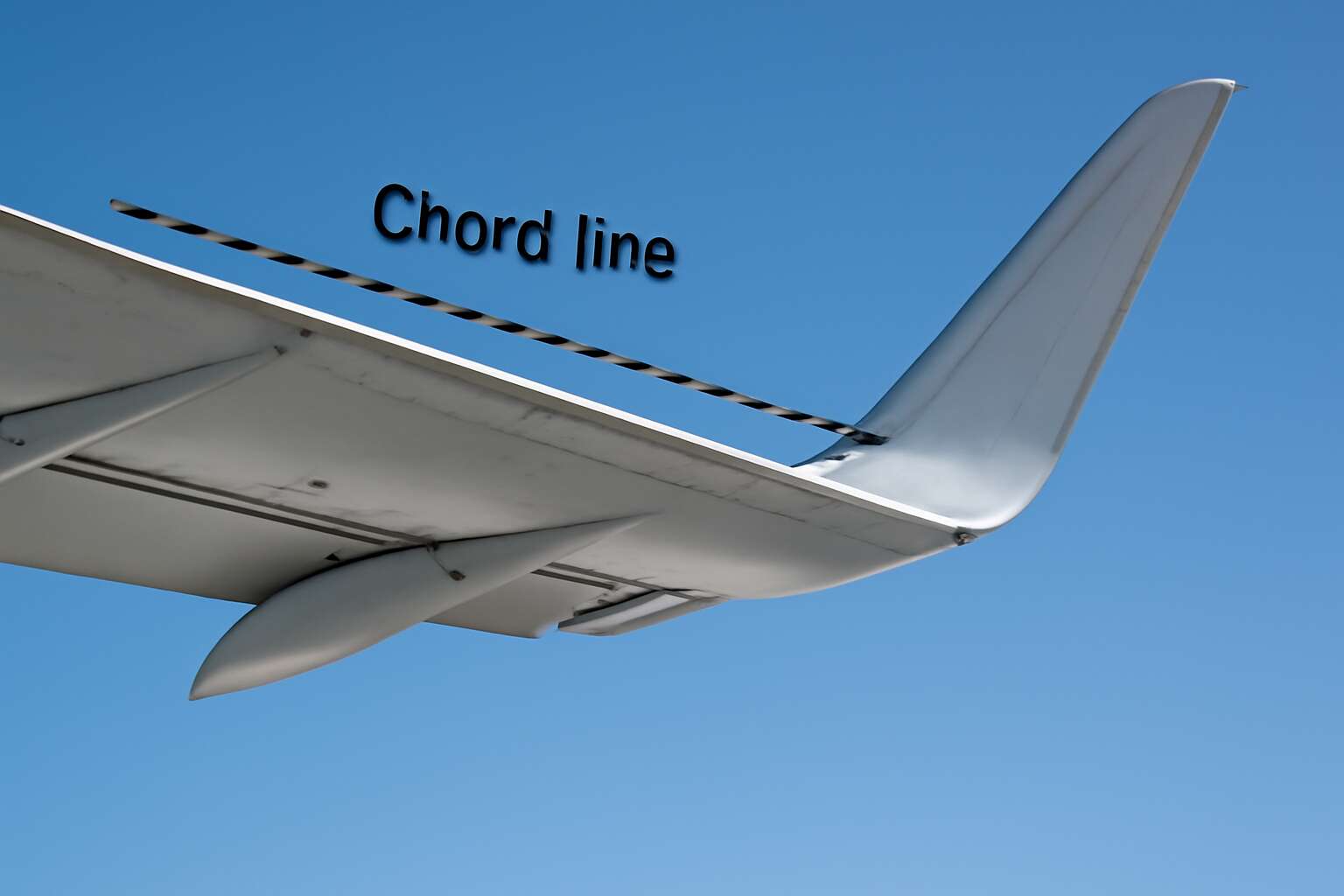

In the fascinating world of aeronautics, understanding the concept of aeroplane chords is essential for anyone passionate about aircraft design and aerodynamics. At its core, an aeroplane chord refers to a straight line connecting the leading edge and the trailing edge of an airfoil, which is the cross-sectional shape of a wing. This seemingly simple measurement holds immense significance in determining how an aircraft generates lift and responds to airflow.

By analyzing the aeroplane chords, engineers and pilots gain deeper insights into the aerodynamics of different wing profiles. Variations in chord length influence the wing’s performance characteristics, such as speed, maneuverability, and fuel efficiency. For example, longer chords often mean greater lift capacity but may also increase drag, affecting overall flight stability. Whether designing sleek fighter jets or cargo planes, understanding aeroplanes chords is fundamental in optimizing aircraft for specific missions and environments.

- Chord length

- Wing efficiency

- Lift generation

- Aerodynamic performance

Importance of chords in aviation

In the grand tapestry of flight, the significance of aeroplanes chords is nothing short of legendary. These seemingly simple lines, stretching from the leading edge to the trailing edge of an airfoil, are the heartbeat of aerodynamic marvels. Their length and shape dictate how efficiently an aircraft slices through the air, transforming raw energy into graceful elevation. It’s a delicate dance—an unseen choreography—that determines an aircraft’s ability to generate lift with finesse and respond harmoniously to the whims of wind and weather.

Understanding aeroplanes chords unlocks a world where engineering meets artistry. Variations in chord length influence wing efficiency, impacting everything from speed to maneuverability. For instance, a longer chord can increase lift generation, making a plane more capable of carrying heavy loads, yet it may also introduce more drag. This intricate balance is vital when designing aircraft for specific missions—whether for swift reconnaissance or cargo transport—highlighting the profound importance of aeroplanes chords in aviation’s evolution.

Basic components of an aeroplane chord

Understanding aeroplanes chords is akin to deciphering the secret language of flight. These fundamental components of an aircraft’s wing structure are more than mere lines; they are the vital arteries that influence aerodynamics in profound ways. By examining the basic components of an aeroplane chord, one gains insight into how wings generate lift and respond to atmospheric whims.

At its core, an aeroplane chord comprises the leading edge, the trailing edge, and the airfoil’s surface connecting the two. This simple yet elegant segment is crucial for determining the wing’s aerodynamic profile. Variations in the chord’s length and shape can dramatically alter an aircraft’s performance, affecting everything from speed to fuel efficiency.

- Leading edge: The foremost part that first encounters the airflow, shaping the initial airflow pattern.

- Trailing edge: The rear boundary where airflow leaves the wing, influencing lift and drag.

- Airfoil surface: The curved section between the leading and trailing edges, designed to optimize lift generation.

In the grand ballet of aviation, the aeroplane chord stands as a silent yet pivotal performer—balancing the delicate interplay between lift, drag, and overall flight dynamics. Its precise design and understanding are essential in tailoring aircraft for their intended missions, be it high-speed pursuits or heavy cargo hauls, especially in diverse environments like South Africa’s varied airspace.

Types of Aeroplane Chords

Chord lengths and their significance

When exploring the world of aeroplanes chords, understanding the different types and their specific chord lengths is crucial. These variations aren’t just numbers—they are the backbone of an aircraft’s aerodynamic harmony. Each type of aeroplanes chords serves a unique purpose, influencing everything from lift generation to fuel efficiency. In essence, the right chord length can make or break an aircraft’s performance, turning a routine flight into a symphony of precision.

Among the various aeroplanes chords, the most common types include root chords, mean aerodynamic chords, and taper chords. These are not arbitrary measurements; they are carefully calculated to optimize aerodynamics. For instance, the mean aerodynamic chord (MAC) often determines the aircraft’s center of gravity and stability. Knowing the precise length of these chords is essential for aircraft design and maintenance, especially in South Africa, where diverse flight conditions demand meticulous attention to detail.

- Root chord: The chord length at the wing root, crucial for lift and structural integrity.

- Mean aerodynamic chord: An average chord length that influences stability and control.

- Taper chord: The chord length at the wingtip, affecting aerodynamics and fuel consumption.

In the realm of aeroplanes chords, the significance of each measurement extends beyond theory. It’s about creating a harmonious balance—one that ensures safety, efficiency, and performance. Whether designing new aircraft or analyzing existing models, understanding the nuances of aeroplanes chords remains an essential skill for aviation professionals in South Africa and beyond. Each chord length tells a story—one of engineering mastery and the pursuit of flight perfection.

Different chord profiles

Different aeroplanes chords come in a variety of profiles, each tailored to serve a specific aerodynamic purpose. These profiles aren’t just arbitrary shapes; they are carefully designed to optimize lift, drag, and fuel efficiency. For example, the taper chord, which narrows toward the wingtips, enhances overall aerodynamic performance by reducing drag and improving fuel economy. Meanwhile, the root chord provides the foundation for the wing’s structural integrity and proper lift distribution.

Understanding these various chord profiles is essential, especially when designing or maintaining aircraft in South Africa’s diverse flying conditions. Here’s a quick look at some common types:

- Root chord: The widest part of the wing near the fuselage, vital for lift and strength.

- Mean aerodynamic chord: The average length that influences the aircraft’s stability and center of gravity.

- Taper chord: The wingtip’s narrower section, crucial for minimizing drag and optimizing fuel consumption.

Each of these aeroplanes chords plays a critical role in balancing performance, safety, and efficiency—an intricate dance that defines the art of aviation engineering.

Chord variations across aircraft models

When it comes to aeroplanes chords, one size definitely doesn’t fit all—especially across the diverse fleet of aircraft gracing South African skies. Different aircraft models sport varying chord configurations, each tailored to meet specific aerodynamic goals. For instance, some fighter jets flaunt ultra-tapered chords to slice through the air with minimal drag, while a cargo plane’s broader chords prioritize strength and lift. Understanding these chord variations isn’t just for aeronautical engineers—pilots and maintenance crews benefit from knowing which chord profile optimizes performance in the unpredictable South African climate.

Among the common types of aeroplanes chords, you’ll find:

- The root chord, which anchors the wing’s structure and bears the brunt of lift generation.

- The mean aerodynamic chord, carefully calculated to influence aircraft stability and balance.

- The taper chord, narrowing gracefully toward the wingtips, reducing drag, and boosting fuel efficiency—an aviation designer’s secret weapon.

From the sleek taper to the robust root chord, each variation in aeroplanes chords plays a pivotal role in balancing safety, efficiency, and performance—truly a testament to aviation’s intricate engineering dance. And in a country where every flight counts, understanding these chord differences can mean the difference between soaring smoothly or struggling against the wind.

Design Principles of Aeroplane Chords

Aerodynamic considerations

In the shadowed realm of aeronautical engineering, the design principles of aeroplanes chords reveal a haunting harmony between form and function. These slender strips, stretching across the wings like veins of steel and shadow, dictate the very soul of flight. Their aerodynamic considerations are not mere technicalities—they are the silent guardians of stability and grace amidst turbulent skies.

The curvature and tapering of aeroplanes chords influence airflow, whispering secrets known only to the wind. When meticulously crafted, they carve a path through the ether, balancing lift and drag with a precision that borders on the mystical. The variation in chord profiles across different aircraft models echoes the dark poetry of evolution—each shape tailored for a specific purpose, a unique dance with the unseen forces that govern flight.

- Optimized chord length for maximum lift

- Strategic tapering to reduce drag

- Refined profiles to enhance aerodynamic stability

As the aircraft slices through the gloom, the aeroplanes chords serve as silent architects of its destiny—an intricate ballet of engineering woven into every shadow and gust.

Structural integrity and chord design

Structural integrity is the backbone of effective aeroplane chords. Without a robust design, the entire aircraft’s stability and safety could be compromised in turbulent skies. Engineers focus on ensuring that aeroplanes chords are not only aerodynamically optimized but also resilient enough to withstand the stresses of flight. The materials used, combined with precise manufacturing, create a chord profile that balances strength and flexibility.

In designing aeroplanes chords, attention to detail is crucial. The shape, thickness, and tapering of the chord directly influence how well the wing can handle aerodynamic forces. Often, a carefully refined chord profile allows for enhanced stability and improved fuel efficiency. Achieving this delicate balance requires meticulous calculations and testing—highlighting that aeroplane chords are more than simple wing segments; they are engineered to serve a vital structural purpose.

When it comes to chord design, many aircraft incorporate specific features to reinforce the wing’s strength. These include internal reinforcements and optimized tapering techniques. Such measures help distribute stress evenly across the wing, ensuring durability during extended flights. Ultimately, the successful integration of aeroplanes chords into aircraft design exemplifies a union of form and function, seamlessly blending structural resilience with aerodynamic performance.

Lift generation and chord distribution

In the intricate dance of flight, the principles behind aeroplanes chords reveal a fascinating layer of engineering mastery. Lift generation hinges on the precise distribution of chord lengths along the wing span, creating a complex aerodynamic puzzle that pilots and engineers strive to solve. It’s not just about the size of the chord but how its shape and placement influence airflow and pressure differentials.

Design principles of aeroplanes chords include optimizing the chord distribution across the wing to maximize lift while minimizing drag. This delicate balance is often achieved through tapering techniques—gradually narrowing the chord towards the wingtip—to enhance stability and control. Such variations aren’t arbitrary; they are calculated to produce a smoother airflow, reducing turbulence and improving fuel efficiency.

- Strategic placement of chord variations

- Refined tapering for aerodynamic harmony

- Internal reinforcements to support structural demands

Understanding how lift is generated through chord distribution unlocks the secret to high-performance aircraft. Every curve, taper, and reinforcement within aeroplanes chords plays a vital role—transforming simple wing segments into the backbone of flight. It’s a silent, powerful symphony of engineering precision that keeps our skies safe and efficient.

Materials Used in Aeroplane Chords

Traditional materials

When it comes to aeroplanes chords, the choice of materials isn’t just about whimsy; it’s a crucial factor that determines aircraft performance and safety. Historically, traditional materials like aluminum and steel dominated the scene, providing a sturdy backbone for the wings and fuselage. These materials offered a remarkable balance of strength and weight, making them the go-to for early aviation pioneers and modern engineers alike.

But as technology advanced, so did the materials used in aeroplanes chords. Today, composite materials such as carbon fiber and fiberglass are increasingly popular, thanks to their exceptional strength-to-weight ratios. These modern marvels are not only lighter but also more resistant to fatigue, ensuring that aeroplanes chords remain resilient under the relentless stress of flight. It’s fascinating how these materials have transformed the landscape of aeronautical engineering, allowing aircraft to soar higher, faster, and more efficiently than ever before.

Modern materials and composites

Modern aeroplanes chords are a testament to how far aeronautical engineering has come—think of them as the high-performance athletes of aircraft design. Gone are the days when aluminum reigned supreme; today, composite materials like carbon fiber and fiberglass are stealing the spotlight. These cutting-edge materials are not only lighter but boast an impressive strength-to-weight ratio, making them ideal for enhancing aircraft efficiency.

In fact, the use of advanced composites in aeroplanes chords has revolutionized the industry. They reduce overall weight, which translates directly into fuel savings and increased payload capacity. Plus, their resistance to fatigue means that airplanes can endure the rigors of frequent flights without the dreaded metal fatigue setting in. This resilience ensures safety and longevity, critical factors in modern aircraft design. With the continual evolution of materials used in aeroplanes chords, the sky is truly no longer the limit—it’s just the beginning.

Advantages of advanced materials in chord construction

In the realm of aeronautical innovation, the materials used in aeroplanes chords are nothing short of revolutionary. Gone are the days when rudimentary metals dictated the limits of aircraft design. Today, advanced composites such as carbon fiber and fiberglass dominate the landscape, transforming aeroplanes chords into paragons of efficiency and resilience.

These modern materials boast an extraordinary strength-to-weight ratio, which means lighter aircraft with greater payload capacity and improved fuel economy. The benefits extend beyond mere weight savings; their resistance to fatigue ensures that aeroplanes chords maintain structural integrity over countless flights—an essential factor for safety and longevity. In the ever-evolving world of aviation, the strategic use of these innovative materials ensures that aeroplanes chords are not only more durable but also more adaptable to the demands of modern aircraft design.

By integrating materials like carbon fiber, manufacturers can craft aeroplanes chords that are as resilient as they are lightweight, fundamentally changing the game. And with ongoing advancements, the future of aeroplanes chords promises even greater efficiency, durability, and performance—making the sky not just a limit, but a starting point.

Measurement and Calculation of Aeroplane Chords

How to measure chord length

Measuring the precise length of aeroplanes chords is a fascinating journey into the heart of aircraft aerodynamics. When it comes to calculating the chord length, engineers often start by identifying a specific point along the wing’s span—usually at the root or the tip—where the chord measurement will be taken. This process involves using a measuring tape or laser distance meter to ensure accuracy. The key is to keep the measurement perpendicular to the leading edge, capturing the true width of the chord. For a more systematic approach, some professionals prefer to use scaled diagrams or CAD software to simulate the chord dimensions based on the aircraft’s blueprints.

To streamline the process, here’s a quick overview of how to measure chord length effectively:

- Locate the leading and trailing edges of the wing section.

- Use a ruler or measuring device aligned perpendicular to the wing’s longitudinal axis.

- Record the distance between these two edges at the chosen spanwise point.

- Repeat for different sections if measuring variations across the wing.

Understanding how to measure aeroplanes chords accurately is essential for designing wings that optimize lift and aerodynamic efficiency. Whether working with traditional materials or modern composites, precise chord measurement ensures every element contributes to a safe and soaring flight!

Chord calculation formulas

Precision in calculating aeroplanes chords is a testament to the delicate artistry behind every aircraft’s design. The formulas used for chord calculation are rooted in fundamental aerodynamics, yet their application can reveal the nuanced grace of a wing’s structure. Engineers often employ the simple yet powerful formula:

Chord length = Wing area / Wingspan

This straightforward calculation provides a foundational understanding, but in practice, measurements are often refined through detailed analysis of sectional profiles. For example, when assessing the chord variation along the wing’s span, professionals might use a series of measured points and interpolate the data to understand how the chord tapers from root to tip. Modern digital tools, such as CAD software, seamlessly integrate these calculations, offering unparalleled accuracy and visual clarity.

In the realm of aeroplanes chords, each measurement is a piece of a complex puzzle—balancing aerodynamic efficiency with structural integrity, all while capturing the poetic symmetry that elevates flight. The art of precise chord calculation becomes not just a technical necessity but a celebration of how engineering lifts us toward the skies, one carefully measured chord at a time.

Interpreting chord data in aircraft design

Interpreting chord data in aircraft design is akin to deciphering the subtle language of flight. Each measurement tells a story—of lift, stability, and aerodynamic finesse—that engineers meticulously analyze to optimize performance. When assessing aeroplanes chords, precision becomes paramount; even minor deviations can ripple across the aircraft’s efficiency and safety.

To accurately understand how chords influence aircraft behavior, professionals often employ advanced digital tools, like CAD software, that streamline data analysis. These platforms allow for detailed visualization of chord variation across the wing span, revealing how tapering or chord extensions impact lift distribution. For example, the use of ordered lists helps clarify complex processes:

- Measuring sectional chord lengths at multiple points along the wing.

- Interpolating data to model the gradual change from root to tip.

- Applying refined calculation formulas to ensure design accuracy.

Such meticulous interpretation of aeroplanes chords ensures that every component aligns with aerodynamic principles, balancing the delicate dance between lift generation and structural resilience. In essence, understanding how to measure and analyze chord data elevates aircraft performance, turning raw measurements into a symphony of engineering mastery that keeps us soaring through the skies with confidence.

Applications of Aeroplane Chords in Aircraft Design

Wing optimization strategies

In modern aircraft design, the application of aeroplane chords plays a critical role in wing optimization strategies. Engineers carefully analyze the chord length and profile to enhance lift distribution, ensuring the aircraft performs efficiently across diverse flight conditions. By adjusting the aeroplane chords along the span of the wing, designers can achieve a more aerodynamic shape that reduces drag and improves fuel economy. This meticulous process involves balancing structural integrity with aerodynamic efficiency, a challenge that is as much an art as it is science.

Advanced computational techniques now allow for precise manipulation of aeroplane chords, enabling the development of wings with varying chord profiles tailored to specific flight requirements. For instance, some aircraft incorporate an elliptical chord variation to optimize lift, while others utilize tapered chords for better structural support. These innovations are vital in crafting wings that are both resilient and adaptable, ultimately leading to safer and more sustainable flight experiences for passengers and crew alike.

Impact on flight performance

In the realm of aircraft design, the application of aeroplanes chords has a profound influence on flight performance. By fine-tuning the chord length and profile, engineers craft wings that glide through the air with remarkable efficiency. This meticulous adjustment impacts lift generation, enabling aircraft to achieve optimal altitude and speed while conserving fuel—a crucial factor in modern aviation.

Innovative use of aeroplanes chords allows for tailored wing geometries that adapt to diverse flight conditions. For example, employing a tapered chord profile can enhance structural support without sacrificing aerodynamics. Such precision engineering results in aircraft that are not only resilient but also highly maneuverable, offering smoother journeys for passengers and crew alike.

In fact, the strategic variation of aeroplanes chords across the wing span—be it elliptical or swept-back profiles—serves as a cornerstone in wing optimization strategies. These variations influence the overall lift distribution, directly affecting the aircraft’s ability to perform efficiently during takeoff, cruising, and landing. As a result, aeroplane chords are central to achieving a delicate balance between lift, drag, and structural integrity, ensuring safer and more sustainable flights.

Chord redesign for improved efficiency

When it comes to aircraft design, the art of chord redesign is a game changer — especially when optimizing for efficiency. Aeroplanes chords aren’t just static measurements; they’re dynamic tools that can be tweaked to maximize aerodynamic performance. By adjusting the chord length and profile, engineers craft wings that slice through the air more gracefully, reducing drag and boosting fuel economy. This meticulous process can involve innovative techniques like tapering or sweeping the chord to suit specific flight conditions.

In fact, some of the most advanced aircraft utilize tailored aeroplanes chords to enhance lift distribution and improve overall stability. For example, implementing a variable chord profile allows wings to adapt dynamically during different flight phases. This strategic approach results in aircraft that are not only more fuel-efficient but also more resilient to turbulence and structural stress. The careful redesign of aeroplanes chords is, without doubt, a cornerstone of modern aircraft optimization, making every flight smoother, safer, and more sustainable for the South African skies.

Common Challenges and Solutions

Balancing weight and strength

Balancing weight and strength in aeroplanes chords presents a compelling challenge that can determine the fate of flight efficiency. Engineers grapple with maximizing structural integrity while minimizing unnecessary weight—an intricate dance that influences everything from fuel consumption to overall aircraft performance. The key lies in selecting materials and design strategies that deliver durability without adding bulk, a task that demands both precision and innovation.

Modern advancements in materials, such as composites and lightweight alloys, have revolutionized aeroplanes chords. They allow designers to craft components that are remarkably strong yet significantly lighter. For example, employing a combination of traditional materials and cutting-edge composites can enhance the resilience of the chord without compromising aerodynamic performance. This approach not only improves safety but also enables longer flights and quicker turnaround times.

To navigate these complexities, many experts turn to sophisticated modeling techniques and iterative testing. The goal? Achieving an optimal balance where the aeroplane’s chords contribute to superior lift generation while maintaining structural harmony. Ultimately, this delicate equilibrium is what propels modern aircraft toward greater efficiency and reliability—an ongoing pursuit that continues to shape the future of aviation.

Aerodynamic trade-offs

One of the most persistent challenges in aeroplane chord design is managing aerodynamic trade-offs that directly impact flight efficiency. Engineers often find themselves caught between increasing lift and reducing drag—an intricate balancing act that can make or break an aircraft’s performance. When aeroplanes chords are too thick or too thin, they can cause turbulence, increased fuel consumption, and compromised stability. These issues highlight the importance of precise chord profiles tailored to specific flight conditions.

To address these complexities, many experts turn to innovative solutions that optimize the aeroplane chords for maximum aerodynamic efficiency. For instance, employing a combination of traditional and modern materials enables the creation of chords that are both resilient and lightweight. Additionally, computational fluid dynamics (CFD) allows for detailed simulations to refine chord shapes without costly physical prototypes. Such advancements help strike a balance where aeroplane chords contribute to smoother airflow and improved lift generation, ultimately enhancing overall aircraft performance.

Innovations to overcome design limitations

Designing aeroplanes chords isn’t without its hurdles. One of the most persistent challenges is overcoming structural limitations while maintaining optimal aerodynamics. Engineers often grapple with the delicate balance between creating chords that are resilient enough to withstand stress yet streamlined enough to minimize drag. This challenge becomes even more complex when considering the diverse range of aircraft models and their specific flight requirements.

Innovative solutions have emerged to address these limitations. Advanced materials and composite technologies are pushing the boundaries, allowing for aeroplanes chords that are both lightweight and durable. Moreover, the adoption of computational fluid dynamics (CFD) has revolutionized the way designers approach chord shape optimization. By simulating airflow in virtual environments, engineers can refine chord profiles to enhance lift and reduce turbulence without costly physical prototypes.

- Utilization of modern composite materials enhances structural integrity while reducing weight.

- CFD simulations enable precise tuning of aeroplanes chords for different flight conditions.

- Innovative manufacturing techniques allow for complex chord geometries to be produced efficiently.

These advancements exemplify how technological innovation continues to elevate aeroplane chord design, ensuring aircraft are not only more efficient but also safer and more reliable in the skies of South Africa and beyond. As the industry evolves, so too does the potential for aeroplanes chords to push the limits of flight performance even further.

Historical Evolution of Aeroplane Chords

Early aircraft chord designs

The evolution of aeroplanes chords embodies a captivating narrative of ingenuity and adaptation, echoing the relentless pursuit of flight efficiency. In the earliest days of aviation, designers relied heavily on rudimentary chord structures, often crafted from solid timber or simple metal frameworks. These initial aeroplane chords were primarily dictated by the constraints of available materials and rudimentary understanding of aerodynamics, resulting in designs that prioritized brute strength over optimized lift. As the understanding of lift distribution and airflow dynamics deepened, so too did the sophistication of aeroplanes chords, gradually shifting towards more nuanced profiles that enhanced performance.

By the mid-20th century, innovations in materials and aerodynamics prompted a significant overhaul of traditional chord designs. The introduction of lightweight composites and advanced engineering techniques allowed for intricate chord variations across aircraft models, tailored to specific flight regimes. This period marked a pivotal shift where aeroplane chords were no longer static elements but dynamic tools for aerodynamic fine-tuning. The interplay between structural integrity and aerodynamic efficiency became central to modern aircraft design, fostering a new era where aeroplane chords could be meticulously optimized to balance weight, strength, and performance.

Advancements in chord technology

The evolution of aeroplanes chords is a story of relentless innovation. Early aircraft relied on basic chord designs made from timber and simple metals, dictated by material limitations and nascent aerodynamic theory. These rudimentary chords prioritized structural strength over optimal lift, often resulting in less efficient flight performance. As understanding of airflow and lift distribution improved, so did the sophistication of aeroplanes chords. Designers began experimenting with varied profiles to enhance aerodynamic efficiency.

By the mid-20th century, advancements in materials—such as lightweight composites—and engineering techniques revolutionized aeroplanes chords. The introduction of flexible and intricately shaped chord variations allowed aircraft to adapt to specific flight regimes. This period marked the beginning of using aeroplanes chords as dynamic tools for fine-tuning performance. Today, modern aircraft leverage advanced materials and precision engineering to optimize chord design, balancing weight, strength, and aerodynamics for peak efficiency.

Future trends in aeroplane chord development

As the shadows of technological progress lengthen, the future of aeroplanes chords beckons with an eerie promise of innovation. The relentless pursuit of aeronautical perfection whispers secrets of lightweight materials and adaptive wing designs that could redefine flight itself. Imagine chords that morph mid-flight, responding to aerodynamic demands with a ghostly elegance, optimizing lift and reducing drag in real time.

Emerging trends suggest a convergence of smart materials and artificial intelligence, ushering in a new era where aeroplanes chords aren’t just static components but dynamic entities. Researchers are exploring flexible, shape-shifting chords that seamlessly balance strength and agility. Such advancements could lead to wings that adapt their chord profiles on the fly, a hauntingly efficient ballet of engineering precision. This evolution promises to elevate efficiency to spectral heights, transforming how aircraft perform in the turbulent skies ahead.

0 Comments